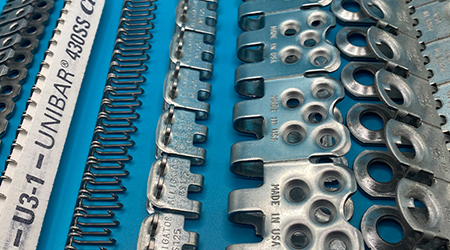

Positive Drive & Monolithic Belting Products

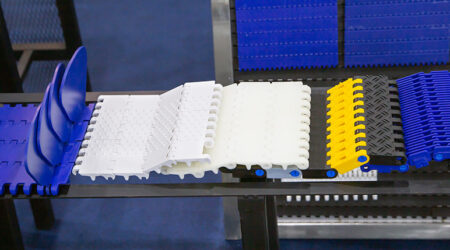

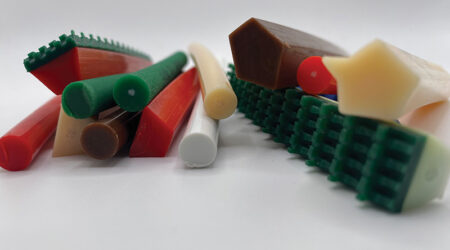

Shipp Belting’s positive drive belts are a highly hygienic and versatile solution that has replaced fabric reinforced and modular plastic belts in many applications. Our positive drive belts offer sprocket driven capacity, which reduces belt slipping, and its one-piece construction features less bacteria harbor points than modular plastic construction.

A lighter weight construction promotes less horsepower and energy consumption, and it’s easy to change or remove. The belt is designed with clean-in-place non-removal capability. The lack of exposed fabric also allows a reduction of odors from contamination. The positive drive belt can be connected by stainless steel fasteners or continuous vulcanization, and it is suitable for fabrication of flights, tracking guides, sidewalls, and perforations. Overall, the positive drive belt is ideal for industries that require a safer, hygienic conveyor belt with less foreign material.

Belt Specs for Positive Drive Belting / Monolithic Belts

Browse our selection of belting product specifications for positive drive and monolithic belts. If you need help finding the right belt for your application, you can contact us directly and our experts can help.

Filter Belt Specs

Looking for More Options? Try Our Belt Finder Tool.

ThermoDrive 8026

Belt Compound: Urethane

Top Surface: Smooth

Bottom Surface: LUG

Color: Blue

Nominal Thickness (in): 2.5

Number of Plies: No Plies

ThermoDrive 8050

Belt Compound: Urethane

Top Surface: Smooth

Bottom Surface: LUG

Color: Blue

Nominal Thickness (in): 3.5

Number of Plies: No Plies

ThermoDrive 8140

Belt Compound: Urethane

Top Surface: Smooth

Bottom Surface: LUG

Color: Blue

Nominal Thickness (in): 2.5

Number of Plies: No Plies

VOLTA-FMB-3 DD

Belt Compound: Urethane

Top Surface: Smooth

Bottom Surface: LUG

Color: Blue

Nominal Thickness (in): 3

Number of Plies: No Plies

VOLTA-FMB-3 DD ITO 50

Belt Compound: Urethane

Top Surface: Texture

Bottom Surface: LUG

Color: Blue

Nominal Thickness (in): .118

Number of Plies: No Plies

VOLTA-FMB-3 SD

Belt Compound: Urethane

Top Surface: Smooth

Bottom Surface: LUG

Color: Blue

Nominal Thickness (in): 3

Number of Plies: No Plies

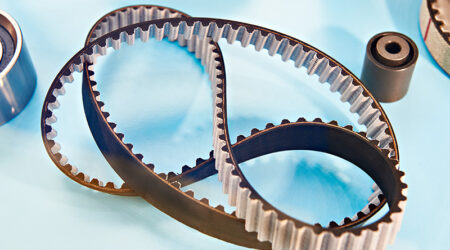

Reduce Costs & Improve Production Efficiency

Easy to Maintain

Positive drive conveyor belts offer several energy and cost reduction benefits that can help businesses improve their bottom line. These belts are designed to reduce slippage, which can lead to energy waste. They also require less maintenance than traditional belts, which can help lower operational costs. Additionally, their precise and consistent movement can increase production efficiency and reduce downtime, further improving cost savings.

Energy & Cost Efficient Benefits

- 50% Reduction in Time to Clean

- 50% Reduction in Water Usage

- 50% Reduction in Energy Consumption

- 50% Reduction in Labor Costs for Cleaning

Resources for Positive Drive Belting / Monolithic Belts

General Belting Resources

We provide a variety of resources to help our customers maximize the lifespan and efficiency of their conveyor belts.

Tools & Calculators

Proper use of these tools can promote improved belt efficiency and productivity while minimizing wear and tear on your belts and other components.