Customization Options for Conveyor Belt Systems

Every belting application is unique and may require a tailored approach. That’s why we offer a variety of customization options for our belting products to ensure that your system needs are met. We work closely with our customers to understand their specific requirements and recommend the best options to optimize their system’s performance.

Our customization options include covers, profiles, cleats and much more that will help you to meet your specific product handling needs. We take pride in offering high-grade belting products that are reliable and built to last, ensuring that our customers receive the best possible value for their investment.

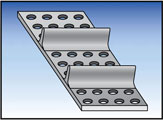

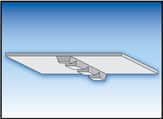

Rubber, Nitrile, Butyl, and PVC Cleats

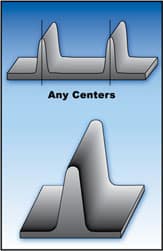

STANDARD I CLEATS

- For conveying up steep inclines

- Available in white FDA or black oil-resisting nitrile, black SBR rubber, black and white butyl

- Cleats are hot molded into the belt surface (not cold bonded or cemented on)

- Smooth merging of cleat and belt cover for easy cleaning

Cleats can be molded to the belt surface on any center, to fit a wide variety of applications. Cleats come in heights from 1/2″ to 5″; (Beefy Cleats to 6″).

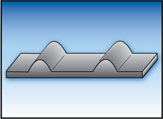

MINI CLEATS

Mini-cleats are low-profile cleats ideal for moving products up inclines in light-duty applications. Unique shape allows for standard idler support on returns. Dimensions are 3/16″ high, 3/16″ wide at base and 1/8″ radius.

STEEL-REINFORCED CLEATS

Super-strong cleat for the most rugged applications. Each cleat features a steel reinforcement oriented to best counter the forces encountered in a particular application.

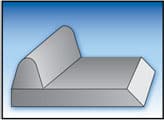

CURVED PVC CLEATS

Ideal cleat for many incline applications requiring food-grade belting. Cleats up to 3″ tall are available in 45° and 30° configurations. Cleats can be applied to belts 6″ to 48″ wide and on centers as close as 4-1/2″ at 30° and 9″ at 45°.

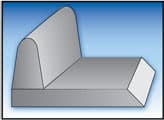

PVC SCOOP CLEATS

White PVC cleats in an angled scoop form to improve capacity up steep inclines. Acceptable for food-handling applications. Available in 2″, 2-1/2″, and 3″ heights, the cleats are hot welded into the belt surface for a smooth, seamless finish.

BEEFY CLEATS

Beefy cleats feature an extra-heavy cross section designed for heavy-duty, rugged applications. Thickness is double that of a standard I cleat. Available in heights from 1″ – 6″, with backup braces available with 2″ and 3″ heights.

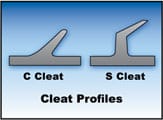

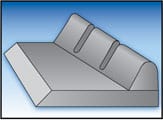

HIGH INCLINE CLEATS

Aggressive scoop cleats for high-capacity conveying on steep inclines. C cleats are available in heights from 1″ to 5″, and S cleats come in heights from 4″ to 4-1/2″. Rugged cleats are hot vulcanized into the belt cover for long service.

LUG CLEATS

Lug construction features rugged V-belt shapes for impact resistance. Available in A (1/2″ W x 5/16″ H), B (5/8″ W x 7/16″ H), and C (7/8″ W x 5/8″ H) cross sections.

PVC VINYL CLEATS

PVC cleats are welded to PVC belting to produce a rugged, economical combination ideal for wet, oily or acidic conditions. Available in black or white FDA compounds and can be spaced on any centers, indented, notched, cut down to intermediate heights and contain cut-outs.

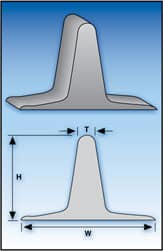

PVC EXTRUDED CLEATS

Extruded PVC cleats are conveniently packaged for distributions and OEMs to manufacture their own PVC cleated belt. PVC cleats are furnished in convenient 100-foot rolls.

| (H) Height | (T) Thickness | (W) Base Width | Min. Pulley Diameter |

|---|---|---|---|

| 1″ | 1/4″ | 1-1/2″ | 4″ |

| 1-1/2″ | 1/4″ | 1-5/8″ | 5″ |

| 2″ | 3/8″ | 1-3/4″ | 6″ |

| 3″ | 3/8″ | 1-3/4″ | 10″ |

Splicing Customizations

ENDLESS – VULCANIZED

A hot-vulcanized splice is stronger and more sanitary than a mechanical (laced) joint. Endless splicing eliminates fastener pull out and tearing of the belt. Ideal for food processing industries and where metal lacing could possibly mar the product.

FINGER SPLICE

A proven-duty splice for thermoplastic belting utilizing polyurethane as the bonding agent. Lap area is the same thickness as the belt and uniformly smooth. H. D. urethane finger splice available for PVC and urethane belts over 200 PIW.

ENDLESS – PREPARED

Belts are supplied with laps already prepared to desired length but not vulcanized, enabling customer to splice endless on the system. Hot or cold cements with instructions are available.

MULTIPLE FINGER SPLICE

Similar to the single Finger Splice. Staggered die cut fingers are vulcanized together to create a strong, extremely flexible splice.

Mechanical Fasteners

LACING STANDARD

Type: Alligator, Clipper, Flexco, Minet and others. Mechanical fastener joints with hinge pins provide an easy, quick and secure method of joining belt ends.

THERMOPLASTIC SOFT SPLICE

This custom splice incorporates vulcanized hidden lacing that derives extra strength from square-cut interlocking fingers. Two flexible connecting pins secure the joint and produce a very consistent thickness at the seam. Soft Splices are applied to thermoplastic PVC and PU material.

SPIRAL LACE

Ideal non-metalic mechanical splice for small-pulley, low-profile applications. Unique hinge design allows use on pulleys and nose bars as small as 5/8″ diameter and as thick as 3/16″. Resists corrosion and heat. Lace is installed in factory by insertion between belt plies.

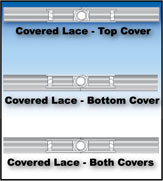

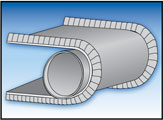

COVERED (HIDDEN) LACE

Lacing is hidden by the cover of the belt to allow the ease of installation provided by a mechanical splice with the smooth operation of an endless belt. Product is protected from marring from the mechanical splice area. Splice can be covered with rubber or abrasion-resistant urethane. If the belt is to be cleaned by a scraper, a hidden top splice is effective. When lacing is completely hidden by the top and bottom covers, both the product and the conveyor are protected.

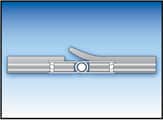

OVERFLAP LACE

Top cover of belt is skived back and mechanical fastener installed. The overflap is spliced back over the splice area, providing a smooth conveying surface. Product being conveyed is protected from marring by the fastener. Flap must be glued down at installation.

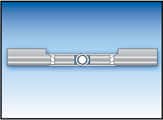

RECESSED LACE

Mechanical splice area of belt is recessed below the level of the belt cover. The recessed lace keeps the product being conveyed from coming in contact with the lacing.

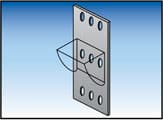

PLASTIC RIVET FASTENERS

Come in white and black, non-metalic compounds for a variety of conveying situations. Fasteners feature beveled edges and counter-sunk pockets in bottom of fastener to protect rivets. Fasteners are either installed by the factory or in the field with special tools.

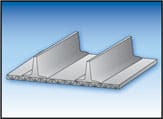

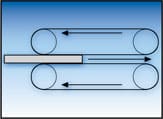

Longitudinal Splicing

Longitudinal Splicing

For extra-wide belt requirements, belts can be made endless, V-guided, and/or flanged. Any width is attainable by using multiple splices. Longitudinal splices can be made in a variety of compounds, including woven PVC, thermoplastic, roughtops, urethane covered, and black rubber in all thickness.

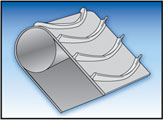

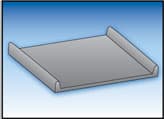

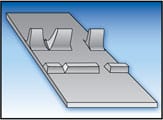

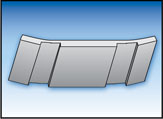

FLANGES

Molded Flanges

Prevents product spilling off edge of belt. Free-flowing materials are contained without troughing. Flange belts can be made endless or conventionally laced. Care must be taken to operate flanged belts on the proper diameter pulleys. Consult factory for recommendations.

FLANGES – HEIGHTS AVAILABLE

1/2″, 3/4″, 1″, 1-1/2″, 2″

Flanges - Styles Available

Gumdrop, Tapered One Side, Tapered Both Sides (all styles not available in all heights) Note: Standard flanges are 60 durometer. 40 durometer is available for special application where smaller than average pulleys are being used

FLANGES – COMPOUNDS AVAILABLE

Black SBR, Black Nitrile, White Nitrile, White PVC, Black PVC, White Butyl High Heat, Black Butyl High Heat

FLANGES – NOTCHED

Notching of the flanges enables a flanged belt to operate on smaller diameter pulleys. Also allows the belt to “back flex” in weighing applications.

FLANGES – SIPED

Siping of flanges enables a flanged belt to operate on smaller diameter pulleys.

FLANGES – SIPED AND DRILLED

Flanges can be siped into relief holes to prevent any further action of slits to propogate into the belt cover.

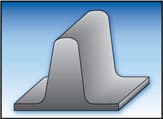

V-Guides and V-Belt Backing

V-GUIDES

Used wherever conditions create a belt alignment problem. Can be molded to any belt and be made endless if desired. Bonded to cover side for flanges; bonded to underside for guide. Available in A(1/2″ W x 5/16″ H), B(5/8″ W x 7/16″ H), and C(7/8″ W x 5/8″ H) cross sections. Other sizes available.

V-BELT BACKING

Covers of pure gum, neoprene sheet rubber, urethane, roughtop belt, white non-marking belt, etc. can be bonded to the back of V-belts.

V-GUIDES – NOTCHED

Available in A-B-C-D sections, and more. Notching enables a V-guided belt to operate on smaller pulley diameters. The V-guide reduces tracking problems.

V-BELT BACKING

Recommended where V-belts are used as conveyor or in tandem to pull product or cable in sandwich fashion.

Edge Finishes

FOLDED EDGES

Premium construction for superior edge wear and carcass protection. Chemicals and bacteria may not attack the interior plies. Folded edges provide a continuous surface from the top of the belt around the edges.

MOLDED EDGES

Rubber edging vulcanized to cut-edge belting. Protects the belt fabric from bacteria and damaging chemicals. Ideal for food-handling applications. Also used for additional protection from edge wear.

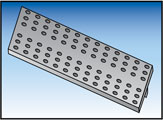

Hole Punching - Perforating

HOLE PUNCHING

Automatic punching assures clean-cut, tight-fitting bolt holes with accurate spacing for the buckets on elevator belting with fast deliveries.

In addition, custom hole patterns are available for chain driven units.

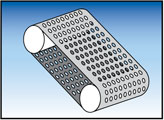

PERFORATED V-GUIDED BELT

V-guides can be placed on a perforated belt to aid in tracking. The entire belt can be perforated, leaving a small strip onto which the V-guide is fastened. Used in vacuum and in drainage applications.

PERFORATING

For vacuum, suction or drainage application. Perforations are clean with no fuzz or tearing. Over 500 dies for hole punching patterns.

PERFORATED CLEATED BELT

Perforated belt can be combined with cleats to create a vacuum belt or a belt that can drain a product while conveying on an incline. Perforations can be of any size and cleats on any centers. Slots available.

Notching

NOTCHING – CLEATS

Cleats can be furnished with notches for troughing idlers or curved pans.

NOTCHING – CHEVRON CLEATS

Notching chevron patterns allows the use of the belt on smaller diameter pulleys. Belts with notched chevrons are often known as “roofers’ belts.”

NOTCHING V-GUIDES

Notching enables a V-guided belt to operate on smaller pulley diameters. The V-guide virtually eliminates any tracking problems.

NOTCHING/SIPING – FLANGES

Notching of a flanged belt enables a flanged belt to operate on smaller diameter pulleys.

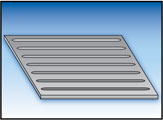

Grooving

GROOVING LATERAL

Grooving across the width of the belt can be used to convey liquid or other free-flowing material.

GROOVING LONGITUDINAL

Grooving can create an economical self-flanging belt for carrying free-flowing material without spillage.

PRECISION GRINDING

PRECISION GRINDING

For applications requiring extreme thickness uniformity across the width of the belt as well as the length. Accurate to ±.005″, precision grinding is available on rubber as well as urethane belts. Often performed on belts used on die stamping applications, precision grinding minimizes any imperfections that might be in the belt cover.

PRECISION GROUD SILICONE TOP COVER BELTS

Used for hot wire sealing applications, balloon manufacturing, and plastic bag manufacturing. Covers are available in a variety of colors and thickness.

- Colors: Cover Red, White or Aqua – other colors are available; base belt: Black

- Plies: 3 (other base belts available)

- Weight: .140 Lbs./Ft2

- Available Widths: 68″ Maximum

- Cover Surface: 1/8″ Precision Ground ±.005″

- Overall Gauge: .25″