CONVEYOR BELTS FOR PAPER RECYCLING APPLICATIONS

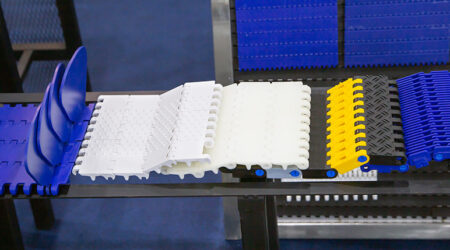

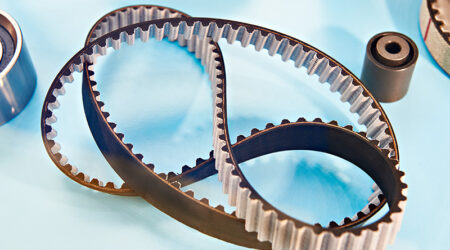

In the specialized field of paper waste and recycling, precision-engineered conveyor systems are essential. These applications demand conveyor belts designed to withstand the unique challenges of handling various types of paper products and recyclable materials. These belts are often customized to enhance the efficiency of sorting, transporting, and processing paper waste. Recycling facilities present environments where the durability and adaptability of belt materials are crucial.

Operational efficiency is key for these conveyor systems. By improving throughput and minimizing downtime, these conveyors streamline the recycling process, ensuring that paper waste is managed in the most efficient, safe, and cost-effective manner possible.

WE MAKE BELTS FOR PAPER RECYCLING APPLICATIONS

STURDY CONVEYOR BELTS FOR PAPER MATERIALS PROCESSING

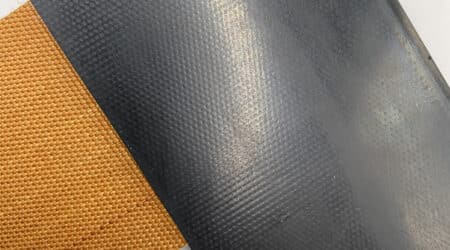

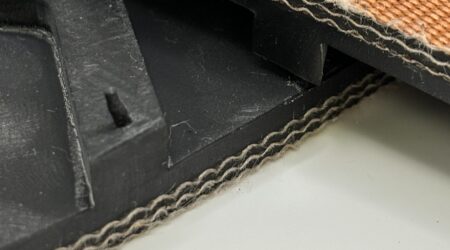

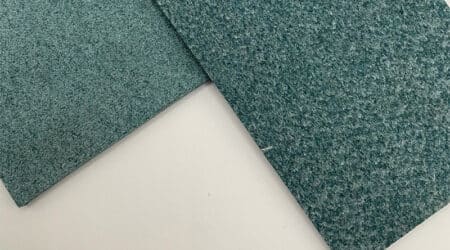

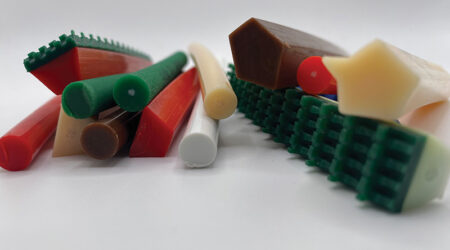

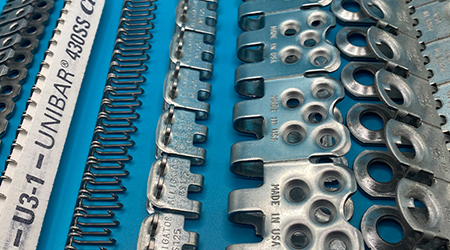

Paper waste, ranging from lightweight to heavy-duty cardboard, presents unique conveying challenges. That’s why our heavy duty conveyor belts are made with high-quality materials and reinforced design.

We engineer these belts to offer exceptional strength and durability, ensuring they can handle a wide range of paper products. This reliability leads to consistent, uninterrupted operations in recycling facilities, where durability is crucial for efficiently managing the diverse nature of paper waste.

OUR BELTS CAN HANDLE A VARIETY OF PAPER PRODUCTS

- Office paper

- Cardboard boxes

- Newspaper

- Magazines

- Books

- Envelopes

- Wrapping paper

- Paper bags

- Packing materials

- Shredded documents

OUR BELT SPECS FOR PAPER RECYCLING APPLICATIONS

Filter Belt Specs

Looking for More Options? Try Our Belt Finder Tool.

2 PLY 150 1/32 x 1×32

Belt Compound: SBR

Top Surface: Smooth

Bottom Surface: Cover

Color: Black

Nominal Thickness (in): 0.156

Number of Plies: 2

200 Crescent Top

Belt Compound: PVC

Top Surface: Crescent

Bottom Surface: Friction Skim

Color: Black

Nominal Thickness (in): 0.303

Number of Plies: 1

220 3/16 x 1/16

Belt Compound: Rubber

Top Surface: Smooth

Bottom Surface: Rubber

Color: Black

Nominal Thickness (in): 0.375

Number of Plies: 2

220-1/8 X Bare(MOR)

Belt Compound: Rubber MOR

Top Surface: Smooth

Bottom Surface: Bare

Color: Black

Nominal Thickness (in): 0.219

Number of Plies: 2

330 1/4×1/16

Belt Compound: SBR

Top Surface: Smooth

Bottom Surface: Smooth

Color: Black

Nominal Thickness (in): .4375

Number of Plies: 3

330 3/16 x 1/16

Belt Compound: Rubber

Top Surface: Smooth

Bottom Surface: Rubber

Color: Black

Nominal Thickness (in): 0.4063

Number of Plies: 3

3ply 330 3/16 x Bare

Belt Compound: SBR

Top Surface: Smooth

Bottom Surface: Bare

Color: Black

Nominal Thickness (in): .375

Number of Plies: 3

3ply 330 V-CLEAT x Bare

Belt Compound: Black MOR

Top Surface: V-cleat (6 inch)

Bottom Surface: Bare RFL

Color: Black

Nominal Thickness (in): .390

Number of Plies: 3

BU210

Belt Compound: Polyurethane

Top Surface: Smooth

Bottom Surface: Friction

Color: Black

Nominal Thickness (in): .16

Number of Plies: 2

BU310

Belt Compound: Polyurethane

Top Surface: Smooth

Bottom Surface: Friction

Color: Black

Nominal Thickness (in): .236

Number of Plies: 3

PV200BB(COS)

Belt Compound: PVC

Top Surface: Smooth

Bottom Surface: Friction Skim

Color: Black

Nominal Thickness (in): 0.203

Number of Plies: 1