Belt Conveyor Maintenance Tips

Maintaining your conveyor system is essential – it helps minimize downtime, reduce costs, and increase productivity. However, it can be challenging to know where to begin when it comes to maintenance. That’s why we offer helpful insights to assist you in keeping your system in top shape. Our team of experts has years of experience in the industry and can provide you with valuable advice and guidance on how to maintain your system effectively. Below, we offer tips on proper belt storage, what to do in the event of belt or hook failure, as well as fastener installation.

If you’re worried about downtime affecting your bottom line, skip the time consuming troubleshooting and contact us to see how we can help.

How To Store Your Belts Safely

To prevent a belt from developing camber (curve), rolls should be stored off the floor in a dry area. They can be suspended on a bar pushed through the center of the roll, or placed on a pallet or skid to keep roll of the floor.

Rolls should NOT BE STORED ON THEIR EDGES because the edges of some belts may absorb moisture from surfaces in which they come in contact. This causes the edge to shrink and become tighter than the opposite edge, resulting in a crooked belt.

What To Do In Case of Belt Failure

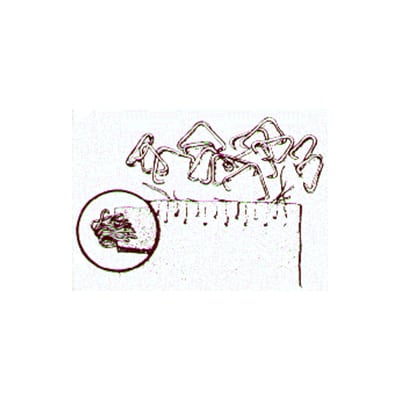

Belt failure occurs when fasteners are stronger than belt and pull out by combing through belt fabric. Prior to failure, holes behind hook legs will become elongated. After pull-out, hooks will remain in fully clinched form and frayed belt fabric will be visible on belt ends.

Check for use of proper size hook (hooks may be too big for belt thickness); a stronger belt may be needed for this application; or possibly need a hook with a longer reach-back.

What to Do In Case of Hook Failure

Hook failure occurs when tension loads exceed fastener strength. In this case hooks will open up in varying degrees (usually starting on one side of joint) and let go of the belt. Increased strain caused by such things as the belt being caught on or hitting conveyor structure or quick tension overloads may result in hook failure.

Check for use of proper size hook (hooks may be too small for belt thickness): Check for belt tracking problem; or possibly use a stronger high-tensile hook.

How To Install Belt Fasteners

Choose the fasteners size on the basis of the overall belt thickness and the diameter of the smallest pulley in the drive. Generally use the smallest fasteners that will fit the belt thickness.

Fasteners size can sometimes be reduced by recessing. Various hinged fasteners can be used to accommodate small pulleys or plate fasteners can be installed on an angle. Make sure that ends of belt are cut perfectly square, otherwise the belt will not track properly. Some fasteners require special hand tools or templates which we can supply.