Emergency Conveyor Equipment Repair Service, 24-Hour Availability

In the world of manufacturing, time is a commodity you can’t afford to waste. Downtime is costly, even when it comes down to a matter of hours. As part of our ongoing commitment to excellence in service, we offer 24-hour service calls, ensuring that help is always just a phone call away, any time of day or night. Whether it’s a sudden breakdown or a critical repair need, our team is ready to respond swiftly and effectively, keeping your operations running smoothly.

Contact Us Directly for Emergency Service

Available 24-Hours a Day

(254) 776-0493

The Importance of Fast Response to the Threat of Downtime

Immediate assistance in times of emergency isn’t just a convenience; it’s a necessity for maintaining continuous production and operational efficiency. When conveyor systems fail, they can bring your entire operation to a standstill, resulting in significant downtime, lost productivity, and financial losses.

Having access to 24-hour service is crucial in these situations. Our rapid response can make the difference between a minor hiccup and a major operational setback, helping to minimize downtime and keep your business moving forward.

What We Offer: Comprehensive 24-Hour Services

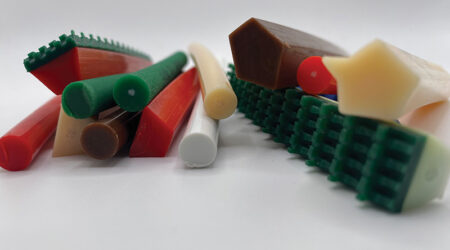

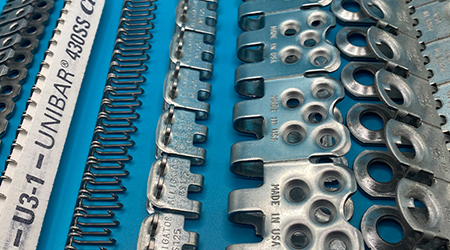

Our 24-hour service availability is designed to cover a broad range of emergency responses, including urgent repairs, thorough troubleshooting, and essential maintenance. From mechanical failure to ordinary wear-and-tear, our team is well-versed in resolving issues with conveyor systems.

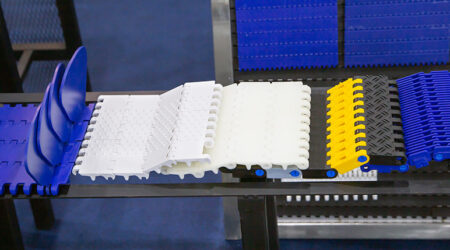

Light-Duty, Heavy Duty, but Never Off-Duty

From light industrial belts to heavy-duty conveyor setups, we understand that each call has its unique challenges. We’re prepared to deliver solutions that are both quick and effective, ensuring that your system is back up and running with minimal delay. Trust us to be your reliable partner in maintaining continuous operation and efficiency, 24 hours a day, 7 days a week.

We’re There When You Need Us Most

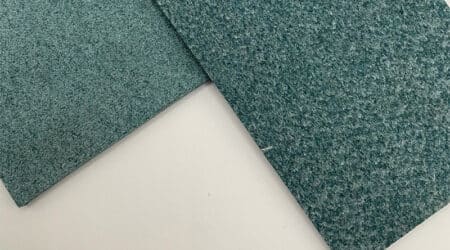

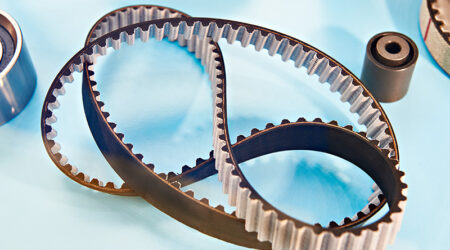

- Conveyor Belt Breakdowns or Tears: Immediate repair or replacement of conveyor belts that have sustained significant damage, causing operational halts.

- Motor Failures: Addressing sudden malfunctions or failures of the conveyor system’s motor, which can lead to complete cessation of the production line.

- Electrical Issues: Troubleshooting and fixing electrical problems within the conveyor system, such as wiring faults or control panel malfunctions.

- Belt Misalignment: Rapid realignment of conveyor belts that have veered off track, potentially risking damage to the product or the system itself.

- Roller and Bearing Malfunctions: Servicing or replacing faulty rollers or bearings that are causing operational inefficiencies or noise issues.

- Accumulator or Sortation System Failures: Resolving issues in complex systems like accumulators or sorters that are critical for managing product flow on the conveyor line.

- Conveyor Belt Tension Issues: Adjusting or fixing the tension of conveyor belts to prevent slippage, overstretching, or other related problems.

- Preventative Emergency Maintenance: Conducting urgent preventative maintenance to avoid imminent breakdowns, particularly in systems showing early signs of wear or potential failure.