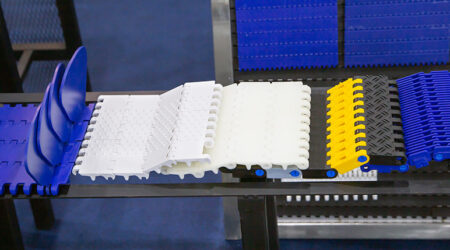

Conveyor Belts for Logistics and Warehouse Distribution

Shipp Belting has been partnering with distribution centers for the past 85 years to maximize their throughput and eliminate downtime. With the recent increase in demand worldwide, our team of solution engineers has risen to meet the challenge and provide our clients with the latest and most innovative technology to keep up with the fast-paced industry.

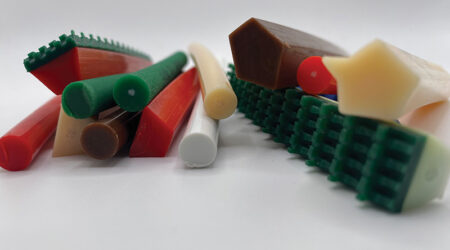

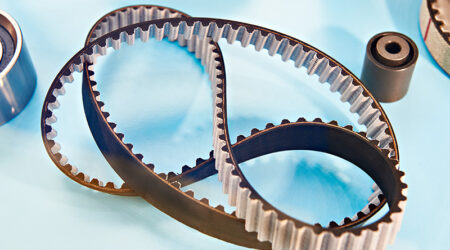

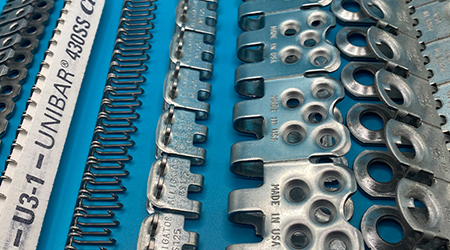

We offer a full range of products, including merging, sorting, power turn, incline, gapping, live roller drive belts, and timing belts that can be found throughout the logistics and warehouse distribution world. Our constant goal is to decrease downtime, increase efficiency, and ultimately save money for our customers.

Our Belting Products for Warehouse Distribution:

- Aramid Cord Flat Belts

- Turn Belts (45-degree, 90-degree, 180-degree)

- Incline Belts

- Gapping Belts

- Optical Sorting

We Make Belts for Logistic and Warehouse Distribution

Conveyor Belts are Critical for Distribution Centers

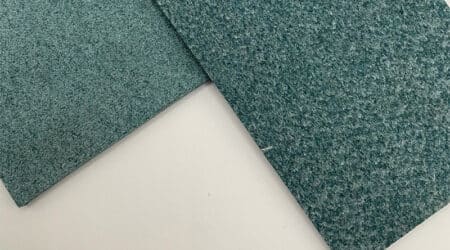

Our conveyor belts are often installed in warehouses and distribution centers for the purpose of sorting, merging, power turning, inclining, and gapping. These tasks are essential for the smooth operation of distribution centers as they help speed up the delivery process and improve overall efficiency. We design our belting solutions to handle a variety of items including small packages, boxes, and even heavy pallets. In addition, we emphasize the ease of maintenance and repair for our components which helps to further reduce labor costs and downtime.

Warehouse Distribution Applications for Our Belts

- Live Roller Drive Belts

- Incline Conveyors

- Merge Conveyors

- Sorting machines

- Palletizers

- Loading/Picking

- Gapping

- Induction