V-Guides for Conveyor Belts

V-guide mechanisms consist of a continuous strip of durable plastic or rubber applied to the underside of the belt. The V-guide strip is designed to fit into a corresponding V-shaped groove on the conveyor pulley, providing additional support and stability to the belt as it moves along the conveyor. This helps to prevent the belt from drifting off track or becoming misaligned, reducing the risk of damage to the belt, conveyor components, and the products being transported.

Belt conveyor V-guides are particularly useful in applications where precise belt positioning is crucial, such as in the packaging, food processing, and material handling industries.

To assure positive tracking within operational standards, it is sometimes necessary to use a V-guide.

Frequently Asked Questions for V-Guides

If I use V-Guides with my belting, will it guarantee I will not have tracking problems?

NO! Just because you use v-guides, it does not mean you don’t have to follow other acceptable practices when designing and building your system. You should strive to have a system and belt that will track by normal means of steering a belt and use the v-guide system to further ensure trackability.

Does a V-Guide fabricated belt require a larger pulley (diameter) than a non-V-guided belt?

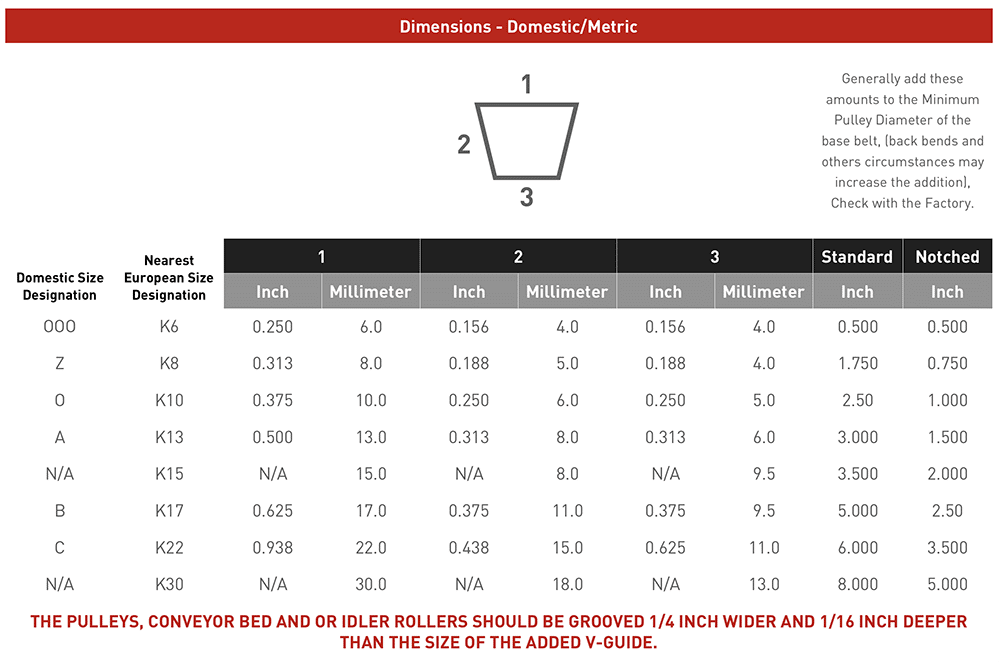

Yes. In general a larger pulley is required when you use a v-guide in conjunction with the belt. A notched v-guide or special segmented urethane v-guide will work on smaller diameter pulleys than standard v-guides. Contact us for recommended pulley diameters for various belts and v-guides.

If one V-Guide is good, are two V-Guides better?

While it seems logical, it isn’t always the case. Sometimes the combination of the belt and the system requires two small v-guides to steer the belt and still flex around the pulleys (versus one larger v-guide that would have difficulty flexing around the pulleys). However, if the v-guides are not placed on the belting with extreme care, you could end up with a situation where the two v-guides are actually working against each other. This can cause premature failure of the v-guides and can cause the guides to lift out of the grooves they are intended to ride in.

We recommend that the v-guide be applied to the center line of the base belt; however, in unusual circumstances, it can be fused off-center. We do NOT recommend the use of more than one v-guide on the pulley surface for tracking purposes. Also, v-guides are meant only to improve tracking…not to drive the belt. Grooves required in pulleys and slider beds to accommodate v-guides must be manufactured both 1/4 inch wider and 1/16 inch deeper than the v-guide size selected to allow for sufficient “play”.