Conveyor Belts for Aluminum Extrusion Manufacturing

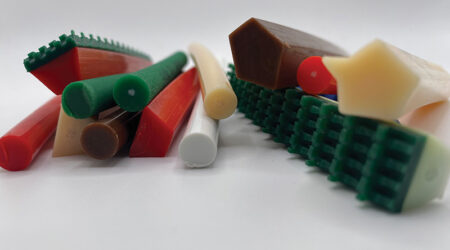

Over the last 30 years Shipp Belting has become one of the industry leading experts and resources for supplying conveyor belt and roller covers in the Aluminum Extrusion Industry. With a wide offering of materials from PBO, Kevlar, Nomex and Polyester, Shipp Belting provides multiple High temperature options that can exceed up to 1200 degrees allowing our customer to eliminate downtime and failure in the most difficult areas.

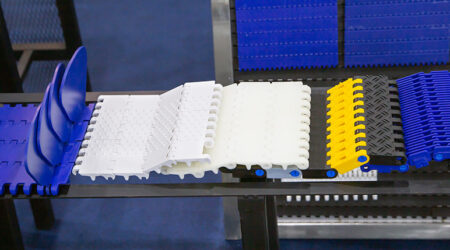

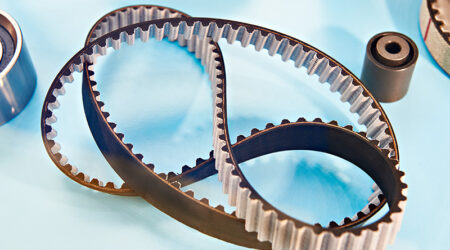

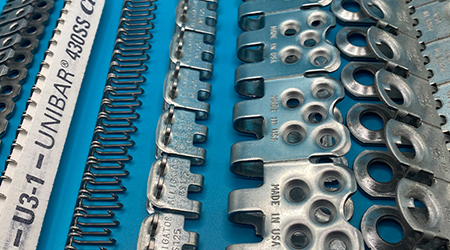

Shipp Belting also supplies a wide range of conveyor components to support the industry ranging from Quench tank rollers, sewn spacer bar covers, needled roller covers, needled pads, needled belts and Kevlar covered timing belts with both spliced and truly endless options.

Our Belting Products for Aluminum Extrusions:

- Kevlar High Temp Belts

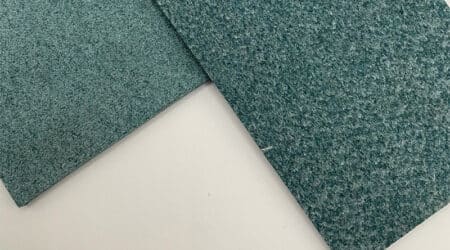

- Spacer Pads

- Spacer Bar Covers

- High Temp Roller Covers

- Quench Tank Rollers

We Make Belts for Aluminum Extrusion Processes

Trust the Experts

Our conveyor belts are commonly used in the aluminum extrusion manufacturing process to transport aluminum profiles or billets through various stages of production. These systems must be designed to handle the weight and size of the materials being transported and able to withstand the high temperatures and pressure involved in the extrusion process without warping or breaking.

At Shipp Belting, we have extensive knowledge and experience within the aluminum extrusion industry and we’ve developed conveying solutions for a wide variety of relevant applications.

Learn More About How Shipp Services Aluminum Extrusion BeltingOur Belt Applications for Aluminum Extrusion

- Extrusion Lines

- Metal Forming

- Tempering

- Aluminum Rod and Bar Extrusion

- Aluminum Billet

- Run Out Table

- Quench Tank Rollers

- Shear table

- Run Out Rollers

- Run Out Transfer Belts

- Stretcher Crossover Belts

- Saw Batching Belts

- Saw Take-Off Belts