Conveyor Belts for Heavyweight Applications

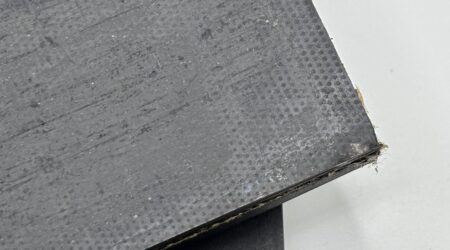

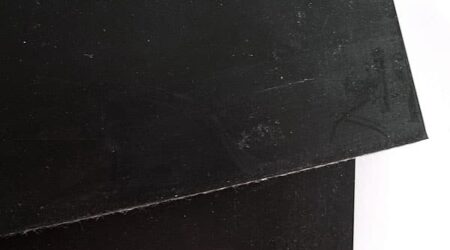

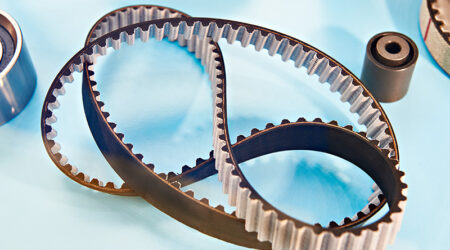

Shipp Belting offers a comprehensive range of heavyweight conveyor belts that are sourced from around the world. Our experts will work with you to provide a belt that is a perfect fit for your application. Our products are available with a variety of cover compounds and cover profiles which enables us to fabricate belts that are highly oil resistant and operational in extreme temperatures.

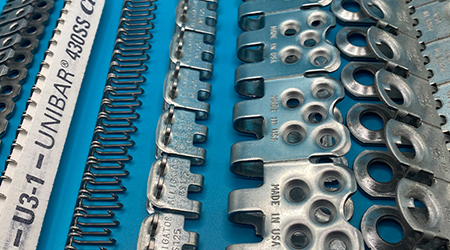

We offer a range of tensile strengths from 150 PIW to 1000 PIW to meet the requirements of various industries. Additionally, our customers can enjoy versatility and convenience through our splicing capabilities, which include Endless, Mechanical fastener or lacing, and Super Screw.

With splicing and winding capabilities up to 96″, put our technicians and equipment to work for you.

Click here for technical data sheet: Shipp Screw Splice

Sidewall Pocket Belts

Bucket Elevators

Overland Conveyor

Belt Specs for Heavyweight Conveyor Belting

Browse our selection of belting product specifications for heavyweight conveyor belts. If you need help finding the right belt for your application, you can contact us directly and our experts can help.

Filter Belt Specs

Looking for More Options? Try Our Belt Finder Tool.

1000 3/8×1/8RC 4PLY GR1

Belt Compound: Rubber

Top Surface: EPDM

Bottom Surface: EPDM

Color: Black

Nominal Thickness (in): .795

Number of Plies: 4

150MINIBITE X Bare

Belt Compound: Rubber

Top Surface: Crescent Top

Bottom Surface: Bare

Color: Black

Nominal Thickness (in): 0.29

Number of Plies: 2

2 PLY 150 1/32 x 1/32

Belt Compound: SBR

Top Surface: Smooth

Bottom Surface: Cover

Color: Black

Nominal Thickness (in): 0.156

Number of Plies: 2

200 Crescent Top

Belt Compound: PVC

Top Surface: Crescent

Bottom Surface: Friction Skim

Color: Black

Nominal Thickness (in): 0.303

Number of Plies: 1

220 1/8 x 1/16

Belt Compound: Rubber

Top Surface: Smooth

Bottom Surface: Cover

Color: Black

Nominal Thickness (in): 0.296

Number of Plies: 2

220 3/16 x 1/16

Belt Compound: Rubber

Top Surface: Smooth

Bottom Surface: Rubber

Color: Black

Nominal Thickness (in): 0.375

Number of Plies: 2

220 3/16 x 1/16 MOR

Belt Compound: Black MOR

Top Surface: Smooth

Bottom Surface: Smooth

Color: Black

Nominal Thickness (in): .344

Number of Plies: 2

220 V-CLEAT MOR

Belt Compound: Rubber MOR

Top Surface: Chevron

Bottom Surface: Rubber

Color: Black

Nominal Thickness (in): 0.3125

Number of Plies: 2

220-1/8 X BAREMOR 2PLY

Belt Compound: Rubber MOR

Top Surface: Smooth

Bottom Surface: Bare

Color: Black

Nominal Thickness (in): 0.219

Number of Plies: 2

225-1/8XBAREMOR3PLY

Belt Compound: Black MOR

Top Surface: Smooth

Bottom Surface: Bare

Nominal Thickness (in): 0.25

250 3/16 x 1/16 RC 1 Ply

Belt Compound: Rubber

Top Surface: EPM

Bottom Surface: EPM

Color: Black

Nominal Thickness (in): .356

Number of Plies: 1

330 1/4×1/16

Belt Compound: SBR

Top Surface: Smooth

Bottom Surface: Smooth

Color: Black

Nominal Thickness (in): .4375

Number of Plies: 3

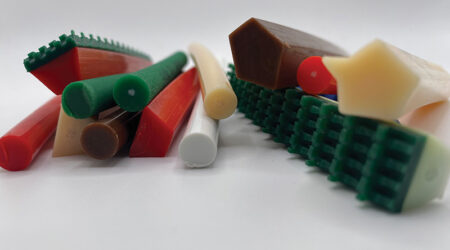

Fabricated To Meet Your Application Needs

We Can Customize Your Belt

Our team of belt conveyor engineers work with hot molded rubber to allow numerous additional fabrication options on your conveyor belts. If you still don’t see what you are looking for, give us a call and see if we can help.

Additional Fabrication Options

- Sidewall

- Tee Cleats

- SI Cleats

- Scoop Cleats

- V-Guides

- Flanges

- Lugs

- Chevron Patterns

- Bucket Perforation Patterns

- Versa Patterns

Resources for Heavyweight Conveyor Belting

General Belting Resources

We provide a variety of resources to help our customers maximize the lifespan and efficiency of their conveyor belts.

Tools & Calculators

Proper use of these tools can promote improved belt efficiency and productivity while minimizing wear and tear on your belts and other components.

Additional Heavyweight Belting Information

Discover the unmatched quality and versatility of bucket elevator belting, designed to meet the diverse needs of all industries. Our extensive range of rubber and PVC belts are available punched to industry-standard patterns, ensuring a perfect fit for your operations. We don’t stop at belting; our comprehensive selection of accessories provides everything you need for seamless bucket replacement and splicing. Whether you require standard Gr-2 compounds or specialized options like fire-resistant and high-temperature materials, we have you covered. With base belting tensions reaching from 120 PVC to an impressive 1200 PIW, our solutions are engineered for high-capacity elevators. Plus, choose from a wide array of durable bucket materials, including fabricated steel, ductile iron, nylon, and urethane, to enhance your operational efficiency.

Discover the exceptional quality and versatility of sidewall belts, meticulously designed to meet the demands of a variety of industries including power generation, cement production, and steel milling. Our belts come equipped with options such as Gr-2, MOR oil-resistant, fire-resistant, and high-temperature covers, ensuring optimal performance even in the most challenging environments. With sidewall heights that range from a compact 1 inch to an impressive 20 inches, our products are tailored to enhance your operational efficiency and reliability.

Our extensive selection of feeder belts stands out in the market, offering an unparalleled variety tailored to meet the specific needs of material handling plants. We provide options such as EPDM high temperature belts, and RMA Grade 1 and Grade 2 belts designed for more abrasive conveying applications. These high-quality belts are essential for accurately measuring and transporting bulk materials, ensuring efficiency and reliability in your operations. By choosing these belts, you are investing in superior performance and durability, making them an ideal choice for any material handling process.

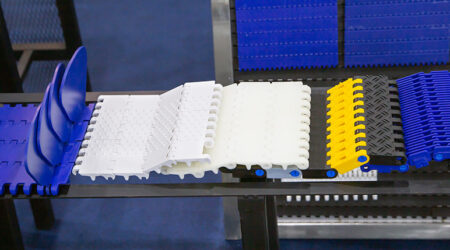

Shipp Belting offers cutting-edge PVC and PU conveyor belt solutions designed to optimize material sorting in various industrial applications. Utilizing innovative technologies such as Eddy Current and Magnetic Separators, our systems effectively segregate non-ferrous and ferrous metals, ensuring efficient processing and minimizing downtime. Our high abrasion and impact-resistant belts are engineered to withstand rigorous operational demands, while high-speed optical and laser sorters enhance sorting reliability and accuracy. Additionally, we provide specialty fabrication tailored to meet specific application needs.

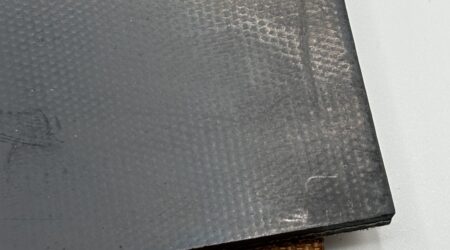

Our 3 ply and 4 ply belting options come with the most durable covers, ensuring longevity and reliability. also offer custom designs tailored to your specifications, including cleats, guides, and various hole patterns. For applications requiring high abrasion resistance, our urethane belts are the perfect solution.