Conveyor Belts for Metal Recycling Applications

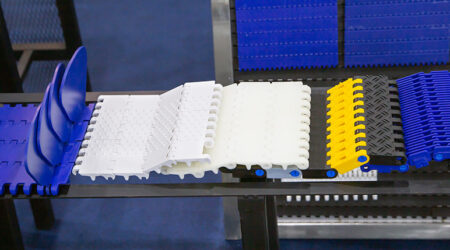

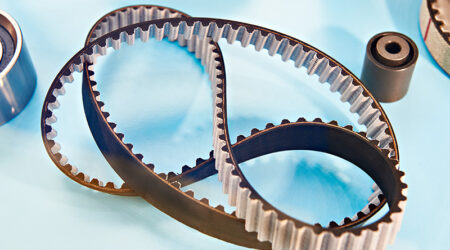

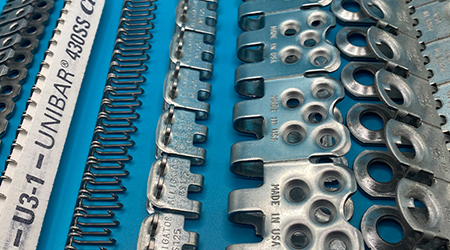

In the demanding world of metal waste and recycling, precision-engineered conveyor systems play a crucial role. These rugged applications require conveyor belts designed to withstand the rigors of handling heavy, abrasive metal scraps and recyclable materials. Often times, these belts are tailored to optimize the efficiency of sorting, transporting, and processing metal waste. Recycling facilities can create harsh conditions where the durability of belt materials is thoroughly tested.

Operations efficiency is critical for these conveyor systems. By enhancing throughput and reducing downtime, these conveyors streamline the recycling process, ensuring that metal waste is handled in the most efficient, safe, and cost-effective manner possible.

We Make Belts for Metal Recycling Applications

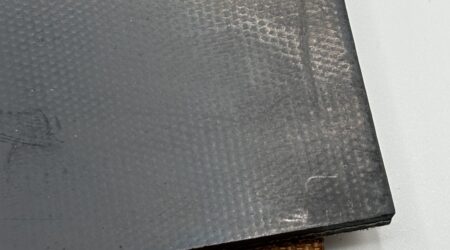

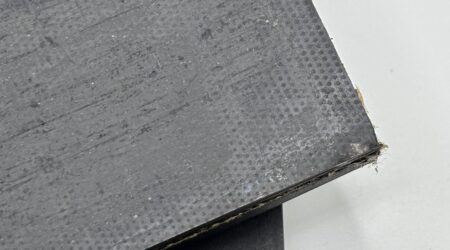

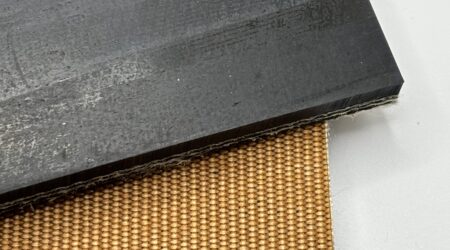

Heavyweight Conveyor Belts for Abrasive Metal Handling

Metal waste is a highly abrasive material that is challenging to effectively convey without the proper equipment and conveyor belts. That’s why our heavyweight conveyor belts are constructed with superior quality materials and multiple plys.

We engineer these special belts to ensure unparalleled durability and abrasion resistance when handling sharp, heavy metal objects. This resilience translates to consistent, uninterrupted operations in recycling facilities, where durability is not just a requirement, but a necessity for handling the harsh realities of abrasive metal waste.

Our Belts Can Withstand Heavy Metal Materials

- Scrap metal

- Wires

- Hardware parts

- Aluminum cans

- Steel beams

- Copper pipes

- Iron sheets

- Car parts

- Metal shavings

- Electrical components

Our Belt Specs for Metal Recycling Applications

Filter Belt Specs

Looking for More Options? Try Our Belt Finder Tool.

2 PLY 150 1/32 x 1/32

Belt Compound: SBR

Top Surface: Smooth

Bottom Surface: Cover

Color: Black

Nominal Thickness (in): 0.156

Number of Plies: 2

200 Crescent Top

Belt Compound: PVC

Top Surface: Crescent

Bottom Surface: Friction Skim

Color: Black

Nominal Thickness (in): 0.303

Number of Plies: 1

220 3/16 x 1/16

Belt Compound: Rubber

Top Surface: Smooth

Bottom Surface: Rubber

Color: Black

Nominal Thickness (in): 0.375

Number of Plies: 2

220-1/8 X BAREMOR 2PLY

Belt Compound: Rubber MOR

Top Surface: Smooth

Bottom Surface: Bare

Color: Black

Nominal Thickness (in): 0.219

Number of Plies: 2

330 1/4×1/16

Belt Compound: SBR

Top Surface: Smooth

Bottom Surface: Smooth

Color: Black

Nominal Thickness (in): .4375

Number of Plies: 3

330 1/8 x Bare

Belt Compound: SBR

Top Surface: Smooth

Bottom Surface: Bare

Color: Black

Nominal Thickness (in): .125

Number of Plies: 3

330 3/16 x 1/16

Belt Compound: Rubber

Top Surface: Smooth

Bottom Surface: Rubber

Color: Black

Nominal Thickness (in): 0.4063

Number of Plies: 3

330 3/16 x Bare

Belt Compound: SBR

Top Surface: Smooth

Bottom Surface: Bare

Color: Black

Nominal Thickness (in): .375

Number of Plies: 3

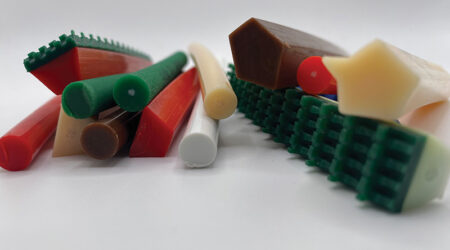

330 V-CLEAT x Bare

Belt Compound: Black MOR

Top Surface: V-cleat (6 inch)

Bottom Surface: Bare RFL

Color: Black

Nominal Thickness (in): .390

Number of Plies: 3

BU210

Belt Compound: Urethane

Top Surface: Smooth

Bottom Surface: Friction

Color: Black

Nominal Thickness (in): .16

Number of Plies: 2

BU310

Belt Compound: Urethane

Top Surface: Smooth

Bottom Surface: Friction

Color: Black

Nominal Thickness (in): .236

Number of Plies: 3

PV200BB(COS)

Belt Compound: PVC

Top Surface: Smooth

Bottom Surface: Friction Skim

Color: Black

Nominal Thickness (in): 0.203

Number of Plies: 1