Conveyor Belts for Meat and Poultry Applications

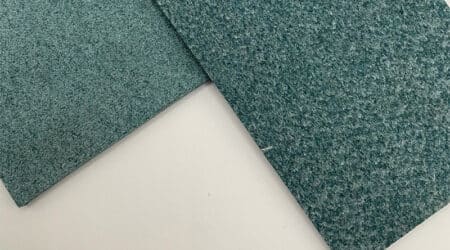

Meat and poultry processors face unique challenges to maintaining food safety and sanitation standards while also meeting production requirements. That’s why why we offer a comprehensive range of solutions for every stage of the food handling process. Our belting products are designed to support live haul, evisceration, chilling, deboning, slicing, cutting, check weighing, packaging, labeling, freezing, and cooling.

As part of our commitment to providing exceptional service and support to our customers, we offer onsite belt welding, emergency service, complete onsite equipment audits, food safety audits, and sanitation cost and labor reduction formulas. Our team of experts is dedicated to finding the right solutions for your specific needs, ensuring that your operation runs smoothly and efficiently.

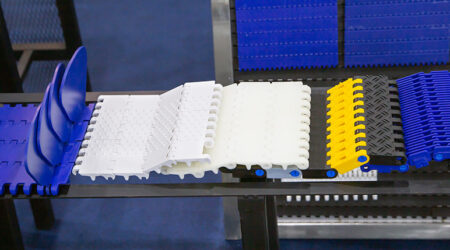

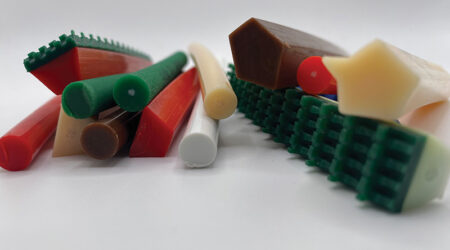

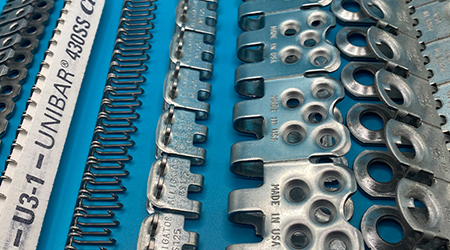

Our Belting Products for Meat and Poultry Applications:

- Slicing Belts

- Meat Block Inclines

- Sausage Belts

- Motorized Pulleys

- Sprockets and Shafting

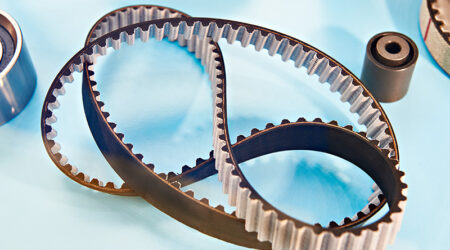

- Timing Belts

- Primary Processing Belts

- Belts for Ready to Eat (RTE)

We Make Belts for Meat and Poultry Applications

Food Safe and Efficient Operations

Food safety standards are important for food processing manufacturers with meat and poultry products because they help to ensure that the food products are safe for consumption and free from harmful bacteria and contaminants that can cause illness or disease. Products that are not handled or processed correctly can contain harmful pathogens like Salmonella and E. coli that can lead to serious health issues for consumers.

Maintaining equipment sanitation isn’t just a regulatory requirement – it also impacts your bottom line. Compliance with food safety standards help to prevent product recalls, which can be costly and damaging to a company’s reputation.

Our Belts Convey Bulk Food Products

- Chicken

- Eggs

- Beef

- Pork

- Lamb

- Goat

- Turkey

- Alligator